Water Like an Oil Well™

Revolutionary Pump Stations with 100 Year Life Cycles

Prefabricated, Modular, Drop-in-Place Water System in a Box™ Technologies

25 Years of Brilliant Water Engineering

Incubating Great Ideas

OriginClear transforms the Water industry, one startup at a time

As infrastructure spending falls far behind, the water industry is now helping commercial water users take charge of their own water needs. Our innovative Modular Water Systems™ team made industrial water systems more compact to fit in these businesses. But, capital remains a barrier for so many firms. That’s where our breakthrough Water On Demand™ fintech enlists everyday investors to help agriculture, industry, and communities recycle their own water without large upfront capital expenses ─ using a pure service model, paying on the meter as they always did with the utility; but this time, with us. Our licensed, compact technologies deliver these private water systems faster, and with patented durability. We're incubating these innovations with more in the pipeline to create the first-ever high tech-style incubator in the water industry, thereby making our most precious resource an investable asset.

Revolutionary water treatment technology meets innovative financing that is turning water into a brand-new asset class – all while safeguarding our most precious resource.

OriginClear's Innovative Water Ventures

For a long time, the government took care of all our water needs. But now, businesses and communities are learning how – and sometimes being forced – to treat their own water, thereby helping reduce the burden on our overloaded city systems. And potentially saving money and precious water by recycling it!

Our mission at OriginClear is to launch amazing new ventures that transform the water industry and improve our most precious asset: life-giving water.

Water On Demand™

Water On Demand™

Water On Demand is the revolutionary water fintech that allows everyday investors to invest in Water Like an Oil Well™ for the first time ever – with the potential for generational royalties. Our vision is to let businesses and communities access vital water treatment technologies, but only pay for the water they use ─ with no upfront capital or expertise required. It’s the future in a world of water rate inflation LEARN MORE

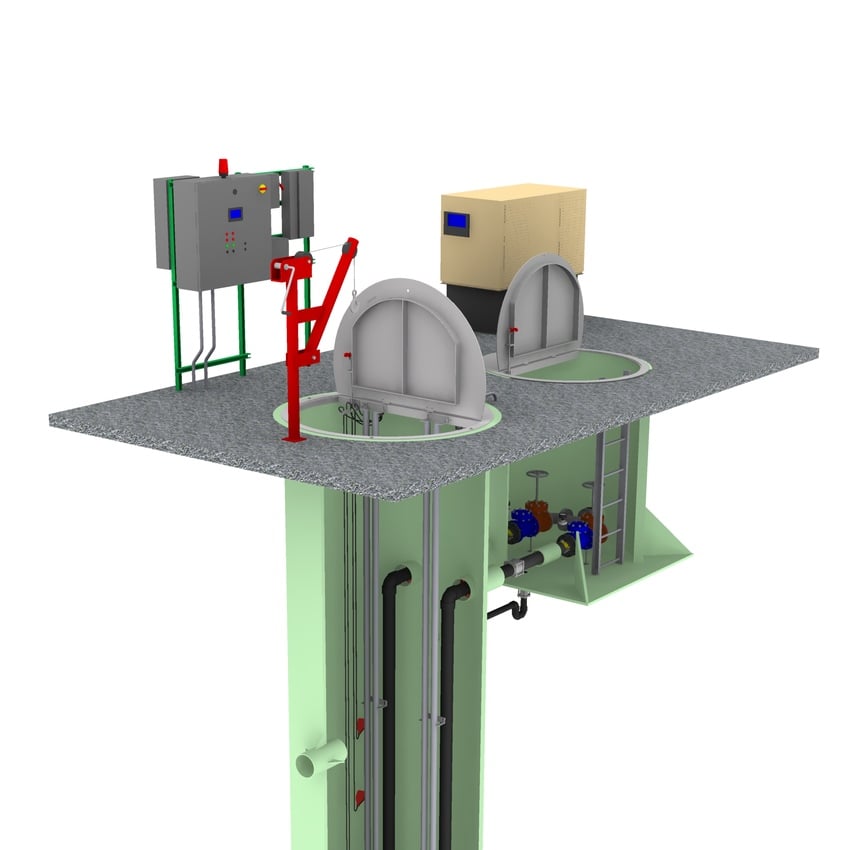

EveraMOD™

EveraMOD™

This next generation, turnkey, single point of delivery infrastructure solution delivers a 100 year structural service life by leveraging a unique design methodology and manufacturing approach brand new to the water industry. EveraMOD replaces conventional and archaic design and procure models built around precast or cast in place concrete, and overcomes previously unsolved durability challenges. LEARN MORE

Progressive Water Treatment™

Progressive Water Treatment™

For 25 years now, Progressive Water Treatment has been able to solve thousands of unique water problems for municipal, industrial, and clean water applications. Progressive Water engineers deliver stand-out, turn-key solutions, as well as services like maintenance contracts, retrofits, and replacement assistance. LEARN MORE

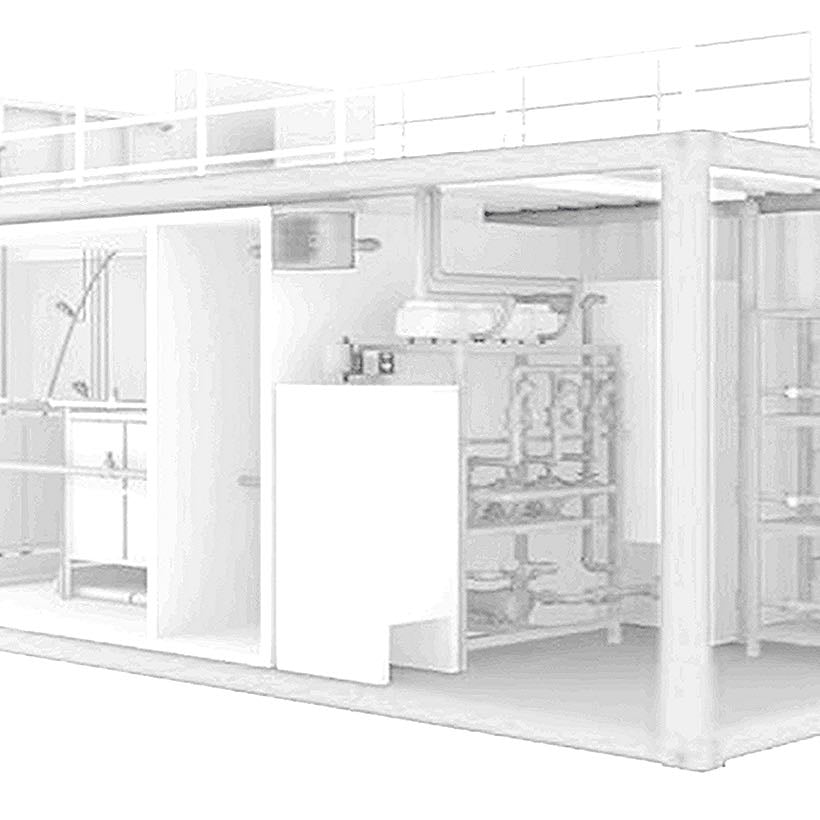

Modular Water Systems™

Modular Water Systems™

Imagine a Water System in a Box™. That's Modular Water Systems—a patented product line that deploys super-durable materials for drop-in-place water projects that solve major problems in the field, with innovation that often results in the coveted "Basis of Design" status that means: only Modular Water can solve this problem! LEARN MORE

From USA Today to Forbes, OriginClear has been making waves across the internet and beyond, spreading the message that water in this world is in trouble – and something can be done about it.

Full Company News Coverage is HERE

OriginClear prides itself on being one of the most transparent public companies around. Every Thursday evening, CEO Riggs Eckelberry hosts a Zoom livestream where he dives into the latest issues and advancements of the trillion-dollar water industry and the investment world, while keeping investors and fans up to date on OriginClear news. You don’t want to miss it!

Sign Up Now For Our Weekly CEO Briefing

OriginClear Tech is accelerating the decentralized water revolution by providing breakthrough technologies and systems that can be rapidly deployed, installed and operating to create instant infrastructure right where it’s needed. Our goal is to help make clean water available for all! LEARN MORE

Did you know that Industry and Agriculture account for about 90% of all water demand, which overwhelms our underfunded, outdated government water utilities? No wonder the remaining 10 percent, the people themselves, suffer water rate inflation and chronic health risks. And already, businesses are starting to do their own recycling, saving them money and taking the burden OFF the central systems. It’s a breakup of a government monopoly, and our Water On Demand™ fintech can enable investors to fund these industrial systems for the first time. That’s the new investable asset, water. And with the cities freed up to serve the people, perhaps someday they might even make the water free, as they do in Ireland?

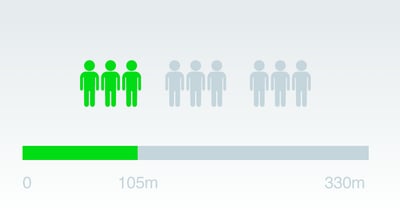

105 million Americans are exposed to unsafe contaminant levels from public water systems

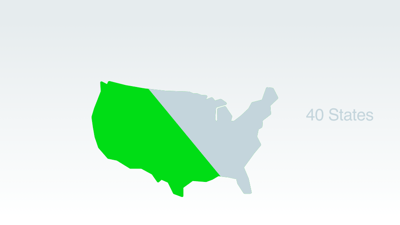

40 US States expect some form of freshwater shortage within the next 10 years.

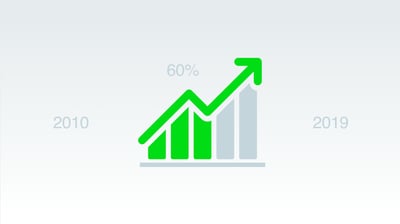

Soaring water rates have increased 60% between 2010 to 2019, 4.25x faster than inflation.

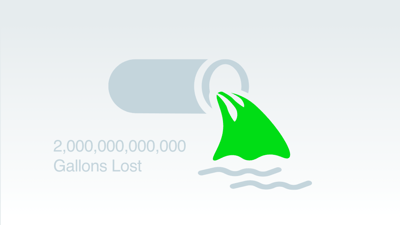

240,000 water main breaks, losing 2 trillion gallons of treated drinking water.

Our innovative companies and initiatives are aiming to revolutionize the trillion-dollar water industry.

You can help - with tremendous financial benefits! We believe this brand-new, inflation-friendly asset class could be bigger than oil and gas...

And way better for the planet.